Changlan Electrical 2024 Social Responsibility Report

1. Company Profile and Main Business

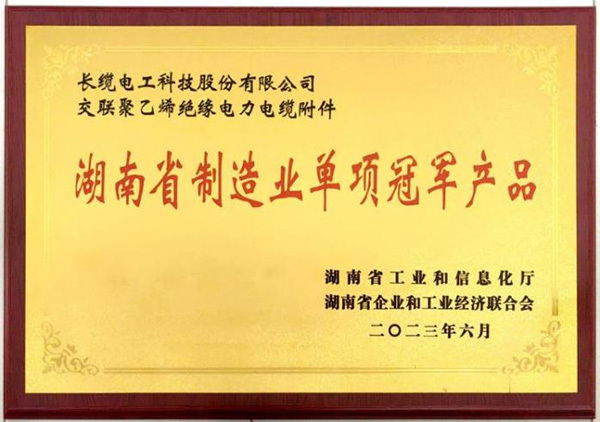

As a leading enterprise in China's cable accessory industry, the company is a national-level high-tech enterprise integrating R&D, production, sales, and service of power cable accessories and products. With over 70 years of technical expertise, the company has established a comprehensive product system covering all voltage levels up to 750kV for AC and DC cable accessories, and possesses R&D and manufacturing capabilities for ultra-high voltage, high voltage, and medium/low voltage cable accessories and products across all specifications. The company offers a comprehensive product portfolio, primarily encompassing three major series: ultra-high voltage cable accessories, high voltage cable accessories, and medium and low voltage cable accessories. Key products include transmission line accessories, communication cable accessories, power hardware, electrical equipment, cable laying systems, insulating materials, and intelligent products. With its outstanding product performance and technological advantages, the company's products have been successfully applied in numerous national key projects and major construction initiatives: in the power grid construction sector, it has participated in the renovation of power grids in megacities such as Beijing, Shanghai, and Shenzhen; in nuclear power engineering, its nuclear power products have been successfully applied in over a dozen nuclear power plant projects including Lingao, Hongyanhe, San'ao, and Lufeng; in the rail transit sector, it has served the construction of subway projects in cities such as Beijing, Shanghai, and Guangzhou; in high-speed rail construction, the company has provided reliable support for major projects such as the Wuhan-Guangzhou High-Speed Railway and the Shanghai-Kunming High-Speed Railway. Additionally, the company's products have been widely applied in the power infrastructure construction of international events such as the Beijing Olympics and the Guangzhou Asian Games, as well as national key projects like the Three Gorges Project, the Xiamen Flexible DC Transmission Project, and the Zhangbei Renewable Energy Demonstration Project. In core market segments, the company has maintained a high market share, laying a solid foundation for stable performance growth. In terms of new market expansion, the company has successfully entered the commercial aerospace sector, achieving the introduction of its materials, cabinets, connectors, and electromechanical products into the aerospace industry. By actively exploring emerging markets, the company is injecting new momentum into its future development. The company's independently developed 500kV AC/DC series products have successfully entered emerging markets such as offshore wind power and pumped-storage hydropower, and have achieved large-scale application in urban grid construction. As an indispensable key product in the fields of power, rail transit, high-speed rail, and other infrastructure construction, the company will continue to drive technological innovation to contribute to the high-quality development of China's power equipment manufacturing industry. In the international market, the company has successfully entered markets in multiple countries including Italy, the United States, Uruguay, Oman, and Algeria, and has achieved export sales of its full range of products. During the reporting period, the company acquired Shuangjiang Energy to enter the transformer insulating oil industry. Shuangjiang Energy is a high-tech enterprise dedicated to the research, development, production, and sales of insulating oil for the power, power grid, and transmission and transformation equipment industries, as well as providing integrated solutions for technical services and product analysis and testing. Its main products are transformer insulating oils, including mineral insulating oil, natural ester insulating oil, and synthetic ester insulating oil. Through years of market accumulation, Shuangjiang Energy has successfully entered the supply chains of several leading domestic transformer manufacturers with its excellent products and services. In the emerging niche market of natural ester insulating oil, Shuangjiang Energy has established a technical and customer advantage. Natural ester insulating oil has a high flash point, high ignition point, is naturally biodegradable, low-carbon, environmentally friendly, non-toxic, has strong overload capacity, and excellent safety, making it an ideal environmentally friendly insulating oil for transformers. Natural ester insulating oil has been successfully applied in projects such as the world's first 110kV natural ester three-dimensional core transformer by Shandong Power and the 180 MW offshore photovoltaic project by the Three Gorges Group in Dongshan Xingchen. Shuangjiang Energy has increased its R&D investment and participated in the national key science and technology project “Key Technologies for the Development of Plant-Based Insulating Oil for Ultra-High Voltage Power Transformers” under the Smart Grid National Key Science and Technology Special Project. By 2025, Shuangjiang Energy will accelerate the deepening of natural ester and synthetic ester insulating oil technology, market expansion, and sustainable development to further respond to global energy transition demands.

II. Core Competitive Advantage Analysis

1. Independent R&D Advantage

① Strong Continuous Innovation Capability

The company is a high-tech enterprise, a key national torch program high-tech enterprise, a Hunan Provincial Enterprise Technology Center, a national green factory, and the依托 unit of the Hunan Provincial High-Voltage Cable Accessories Engineering Technology Research Center. The company has always regarded technological innovation as the driving force behind its development, accumulating successful experience in key technologies such as material formulation, rubber compounding, rubber molding, and epoxy casting molding. By adopting international standards and advanced technologies, the company continuously introduces new products, forming a virtuous cycle of production, development, and planning. The company has independently developed a series of products including 290/500kV cross-linked polyethylene insulated power cable accessories, ±525kV (±535kV) cross-linked polyethylene insulated DC cable accessories, DC cable accessories for voltage levels of 400kV and below, high-speed rail-specific 27.5kV products, and nuclear power and wind power-specific cable accessories, and intelligent online monitoring systems. It is the first company in China to achieve industrialization of 220kV and 110kV series high-voltage cable accessories and one of the first to develop and apply cable accessories for 750kV, ±535kV, ±400kV, and ±320kV systems. The company has invested an average of over 5% of its main business revenue in R&D over the past three years and has continued to increase its investment in recent years, effectively supporting its sustained R&D capabilities for new products.

② Standard-setting strategy

The company is a member of the China Standards Association, continuously monitoring and researching the latest international standard trends, actively participating in the formulation and promotion of national and industry standards, and leading the development direction of the industry. The company participated in the drafting of the following standards: 《Rated Voltage 110kV (Um=126kV) Cross-linked Polyethylene Insulated Power Cables and Accessories Part 3: Cable Accessories》 (GB/T 11017.3-2014), “Rated Voltage 220kV (Um=252kV) Cross-linked Polyethylene Insulated Power Cables and Accessories” (GB/T 18890.3-2015), Rated Voltage 1 kV (Um = 1.2 kV) to 35 kV (Um = 40.5 kV) Extruded Insulation Power Cables and Accessories — Part 4: Test Requirements for Power Cable Accessories for Rated Voltage 6 kV (Um = 7.2 kV) to 35 kV (Um = 40.5 kV) (GB/T 12706.4-2020), “Extruded Insulation Power Cable Systems for DC Transmission with Rated Voltage of 500 kV and Below — Part 4: DC Cable Accessories” (GB/T 31489.4-2020), “Training and Assessment Standards for Cable Accessory Installation Personnel in the Power Industry” (T/CEC194—2018), “Installation Procedures for ±160kV to ±500kV DC Extruded Insulation Cable Accessories” (DL/T 2059-2019), and other 29 standards.

③ Advanced R&D and Testing Facilities

The company's R&D center is equipped with a complete set of laboratories, including product design, material development, process design, mold and tooling design, material performance testing, high-voltage testing, and ultra-high-voltage testing. In terms of testing and inspection, the company has one 800kV ultra-high-voltage testing hall, one 500kV ultra-high-voltage testing hall, three 220kV high-voltage testing halls, six 66-138kV high-voltage testing halls, and seven 10kV-35kV medium and low-voltage testing halls, all equipped with advanced testing and inspection equipment. With its advanced R&D testing facilities and technical expertise, the company has the capability to conduct product development testing, type testing, sampling testing, and factory testing for cable accessories at voltage levels of 800kV and below, and even higher voltage levels. This has laid a solid foundation for the development of cable accessories at different voltage levels and the assurance of product quality.

④ Efficient R&D platform

Leveraging over six decades of technical expertise, the company fully utilizes self-innovation platforms such as the Provincial Engineering Technology Research Center and the Provincial Enterprise Technology Center. By combining talent advantages, technical strengths, and abundant research resources, it has established an efficient R&D innovation system, enhancing new product development efficiency and strengthening the company's self-innovation capabilities. The company also collaborates with the State Grid Electric Power Research Institute and multiple provincial power companies, and has established a joint research center with Xi'an Jiaotong University to enhance the innovative capabilities of technical personnel and the overall level of the scientific and technological team.

2. Marketing Channel Advantages

Guided by an overall marketing strategy, the company has continuously invested in the construction of its marketing system through fundraising projects, deeply advancing its sales network expansion strategy, and focusing on building a three-tiered marketing network covering provincial, municipal, and county-level markets. By optimizing organizational structure and establishing 50 specialized sales teams, the company has achieved refined market coverage and maximized collaborative efficiency.

In terms of marketing model innovation, the company actively promotes a business transformation centered on “customer-centricity and team support,” establishing an integrated incentive system encompassing pricing strategies, tiered authorization, cost control, and mechanism innovation. Through precise market positioning and business boundary delineation, the company continues to deepen its core business areas, penetrating niche markets to enhance market share and brand influence. The company has intensified efforts to develop international markets, expand direct export shares, promptly adjust product structures and sales policies, enhance market control capabilities, and drive sustained performance growth. Strategic adjustments and continuous optimization of the marketing system have not only improved market response speed and service quality but also established differentiated competitive advantages for the company, providing a robust foundation for sustained business growth.

3. Corporate Brand Advantage

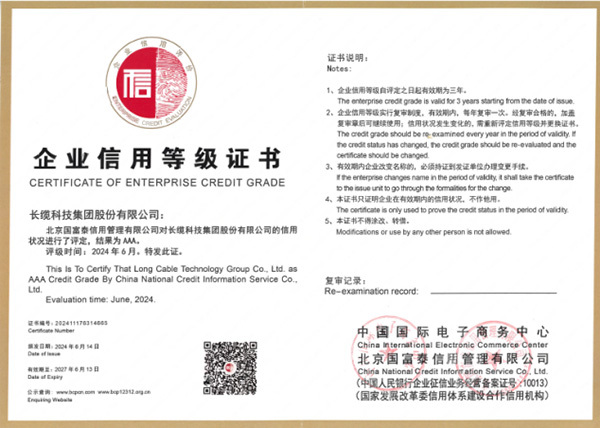

Founded in 1958, the company's products are widely applied in key projects such as power grids, power generation, rail transit, and large-scale engineering. In recent years, as the company's industry status and brand influence have continued to rise, it has received numerous prestigious awards within the industry. The company is a “National Torch Program Key High-Tech Enterprise,” “Outstanding Private Science and Technology Enterprise in China,” “National Model Enterprise for Contract Compliance and Creditworthiness,” “Star Enterprise for the Revitalization of Equipment Manufacturing SMEs,” “Hunan Province Innovative Enterprise,” and “National Green Factory.” The “Changcable” trademark has also been recognized as a well-known trademark in China.

4. Comprehensive Product Range Advantage

The company's product portfolio comprehensively covers the cable accessory sector from 1 to 500 kV, with a particular focus on the design and manufacturing of cable terminals, joints, and配套 hardware for cables up to 500 kV. These products are compatible with various materials, including copper, aluminum, and copper-aluminum transition, and offer a wide range of specifications, from 2.5 mm² to 2,500 mm². Additionally, the company supplies a range of specialized equipment and tools required for cable installation, including hydraulic, mechanical, manual, and electric crimping tools, cable conveying systems, and traction and sliding devices, among other complete sets of cable laying accessories. In terms of materials, the company offers self-adhesive insulating materials, semiconductive tapes, polyurethane casting resins, and other insulating and protective materials, as well as copper braided tapes, copper mesh, lead seals, and other auxiliary accessories for cable joints. Furthermore, the company manufactures a series of cable branch boxes ranging from 0.4kV to 35kV, as well as配套 products for 10kV and 35kV ring main units (cabinet), achieving a full industrial chain layout from cable bodies to distribution equipment. It also provides intelligent systems such as cable body monitoring systems, channel comprehensive monitoring systems, and distribution network online monitoring systems, offering customers a one-stop, high-quality power solution.

5. Quality Control Advantages

The company has obtained ISO 9001 quality management system certification, ISO 14001 environmental management system certification, and ISO 45001 occupational health and safety management system certification. Multiple products, including the “220kV series cross-linked polyethylene insulated cable accessories,” have received international standard product recognition certificates. The company has passed the qualified supplier review of the China National Nuclear Corporation (CNNC) and can provide cable accessories and related products within the certified scope to the CNNC headquarters and its subsidiaries. The company has passed the quality assurance capability review and product testing conducted by the China Railway Inspection and Certification Center, enabling it to supply cable accessories within the scope of certification for railway projects. In daily production, the company strictly adheres to quality management system requirements, continuously improving processes related to product R&D, production, inspection, and customer service. To enhance labor productivity and product quality and performance, the company has imported state-of-the-art production, testing, and experimental equipment from abroad, laying a solid foundation for product R&D and ensuring product quality.

III. Business Philosophy

Integrity and Pragmatism Innovation and Improvement

Integrity is the intangible asset of an enterprise, the core of Changlian Technology's corporate culture, and the inherent quality of self-improvement that has been passed down through generations of Changlian employees. An enterprise cannot stand without integrity. Over the decades of Changlian Technology's development, Changlian employees have consistently upheld the spirit of integrity, conducting business and providing services with honesty and integrity, which has earned the company a good reputation and established a positive corporate image. Pragmatism is the outward character of every Changcable employee. We focus on our work, striving for perfection and excellence; we are dedicated to our jobs, fulfilling our responsibilities diligently, and committed to fulfilling the company's mission of “bringing light to millions of households.” The spirit of integrity and pragmatism has shaped the unique character of Changcable employees, becoming the core of the company's culture. Changcable employees serve society with loyalty and integrity, and develop the company's bright future with diligence and pragmatism.

Innovation is the internal driving force for the company's continuous development. Changlan Electrical has always emphasized technological innovation, institutional innovation, and management innovation, using innovation to drive development. The company has consistently focused on the cable accessory industry, continuously enhancing its research and development capabilities and independent innovation capacity. It adheres to an integrated approach combining industry, academia, and research, continuously integrating the concepts of industrialization and informatization, and has launched a series of high-tech, market-oriented premium intelligent products. Meanwhile, it continuously strengthens its sense of corporate mission and social responsibility, using social responsibility as the guiding principle for brand development and customer satisfaction as the pursuit of responsibility, continuously optimizing products and services to strive to become an internationally leading cable accessory manufacturer.

IV. Stakeholder Communication

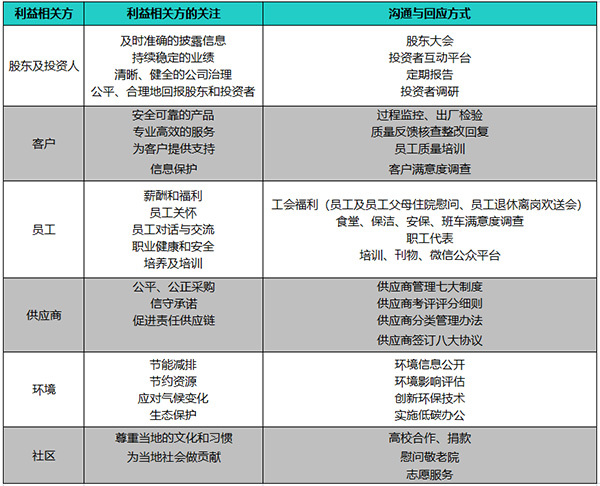

The company upholds its corporate mission of “Connecting Global Cables, Bringing Light to Every Home,” striving to fulfill its social responsibilities while pursuing economic benefits and long-term development, to promote mutual growth between the company and its shareholders, investors, employees, suppliers, customers, and society.

1. Protection of Shareholder and Investor Rights

The company prioritizes safeguarding the interests of shareholders, particularly minority shareholders, and actively rewards investors. During the reporting period, the company established a reasonable profit distribution policy to reward shareholders and investors. The company actively fulfills its information disclosure obligations, strictly adhering to relevant information disclosure requirements. It publishes regular reports, related documents, announcements of resolutions from shareholder meetings and board meetings, as well as announcements of major company events on designated information disclosure media, ensuring that investors can promptly and accurately access company information. Additionally, the company places importance on maintaining investor relations, establishing a good interactive platform, and maintaining effective communication with investors through channels such as investor interaction platforms, telephone communication, and email.

2. Protection of Employee Rights

The company recruits employees through public recruitment in accordance with its talent development plan, actively promoting employment. The company strictly complies with the provisions of the Labor Law and other relevant laws and regulations, signs standardized labor contracts with employees, timely pays social insurance and housing provident fund contributions for employees, and provides various employee benefits including accommodation, shuttle buses, and meal allowances. The company continuously improves its human resources management system, establishes a planning mechanism linking human resources strategy with business strategy, and implements talent development programs to continuously cultivate high-quality R&D and management talent for the company. The company places great emphasis on employee health and safety, conducting regular occupational health examinations for employees. By actively implementing “safety production standardization” and “6S on-site management” initiatives, the company continuously improves its safety production management standards to create a safe working environment for employees. Additionally, to incentivize employee initiative and creativity, retain and attract outstanding talent, the company has successively launched the first and second employee stock ownership plans.

3. Protection of Supplier and Customer Rights

The company consistently adheres to a business philosophy of wholeheartedly serving customers, emphasizing credibility and quality first. The company has established a comprehensive after-sales service system, providing customers with high-quality, high-performance products through advanced manufacturing equipment, testing instruments, and technological R&D; and offering timely, professional installation services through well-equipped installation teams. The company treats every customer with integrity, continuously improving its service system and enhancing service installation standards to provide customers with safe, high-quality cable accessory products, ensuring the safe operation of the power grid. The company strictly controls supply chain access points and continuously improves its supplier management system. Suppliers are selected through open and fair bidding processes. Raw materials and components are procured in accordance with industry standards and environmental protection requirements. The internal testing center conducts rigorous performance inspections on procured raw materials to prevent non-conforming materials from entering the production process.

4. Energy Conservation, Emission Reduction, and Environmental Protection

The company places high importance on environmental protection, clean production, and energy conservation and emissions reduction. During product R&D and production, the company strictly adheres to environmental management system standards, continuously optimizes product structure, strengthens process control, improves production efficiency and material utilization rates, and enhances environmental and performance testing of raw materials, intermediate products, and finished goods. This effectively reduces scrap rates, lowers production costs, achieves energy conservation and emissions reduction targets, and has earned the company the honor of “National Green Factory.”

5. Actively fulfilling social responsibility

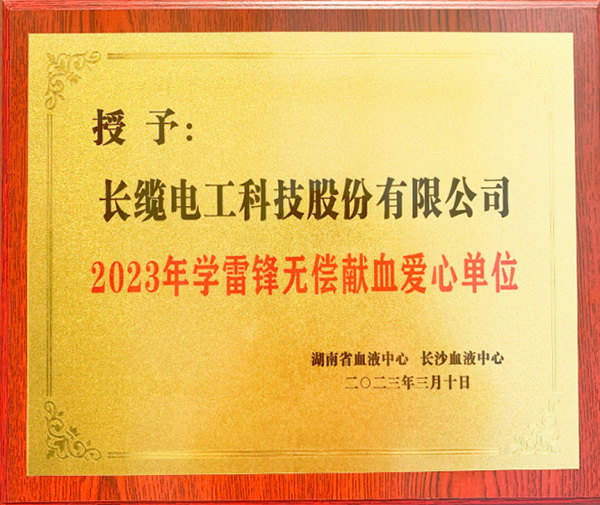

The company actively fulfills its social responsibility by engaging in social welfare initiatives to give back to society. In 2024, Mr. Yu Zhengyuan, the company's actual controlling shareholder, donated 200,000 yuan to the Hunan University Education Foundation in his personal capacity. Since 2018, he has cumulatively donated 1.2 million yuan to the Hunan University Education Foundation. primarily used to reward students with outstanding academic performance and innovative spirit in the field of electrical insulation. Under the organization of the company's Party, Youth League, and Trade Union, the company has conducted voluntary blood donation activities, charitable assistance for the disabled, “River Youth” volunteer services, visits to nursing homes, and visits to employees, among other initiatives, to provide practical assistance to employees and members of society in need, thereby fulfilling its social responsibilities in a concrete manner.

6. Consolidation and Expansion of Poverty Alleviation Achievements and Rural Revitalization Efforts

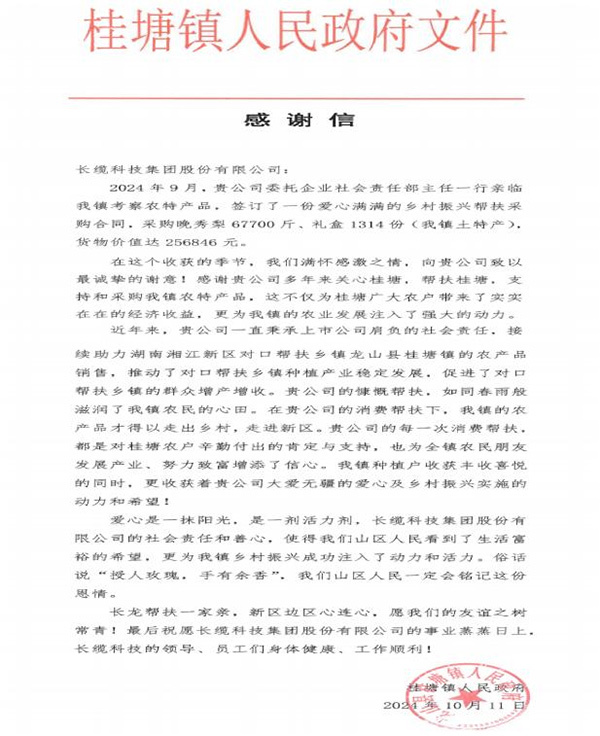

The company actively implements the instructions and requirements of the Party Central Committee, the State Council, and the China Securities Regulatory Commission regarding the consolidation of poverty alleviation achievements and rural revitalization. Through targeted assistance, it actively fulfills its social responsibilities and promotes the effective implementation of township assistance work. In 2024, the company purchased approximately 310,000 yuan worth of agricultural products from Guitang Town, Longshan County, which it assists. Since 2019, the company has continuously supported rural revitalization through the “purchase-based assistance” approach for six consecutive years, contributing a total of over 1.76 million yuan. This has promoted the stable development of agriculture in the assisted townships and facilitated increased production and income for the local population.

5. Adhering to Law-Abiding Operations

Changlian Technology has always adhered to honesty and integrity, civilized operations, and compliance with industrial and commercial administrative laws and regulations. It insists on fair competition and has no adverse credit records in “Credit China,” “Credit Hunan,” or “Credit Changsha.”

Changlian Technology strictly follows the requirements of laws and regulations such as the Company Law, Securities Law, Listed Company Governance Guidelines, and Shenzhen Stock Exchange Stock Listing Rules, as well as normative documents issued by the China Securities Regulatory Commission (CSRC) regarding listed company governance. The company continuously improves its corporate governance structure, voluntarily fulfills its information disclosure obligations, and promotes standardized operational practices. Based on the establishment of internal control systems, the company combines industry characteristics and actual business operations to continuously revise and improve internal control systems. Through daily supervision and special inspections, the company ensures the effective implementation of these systems within the group, providing safeguards for lawful and compliant business operations, asset security, the accuracy and completeness of financial reports and related information, improved operational efficiency and effectiveness, and the achievement of the company's strategic development goals.

VI. Ensuring Production Safety

Continuously promote standardized management and production safety work, and deepen the implementation of the legal representative responsibility system. Adhere to the principles of “managing production must include managing safety,” “managing industries must include managing safety,” and “managing business must include managing safety,” and promote the company's safety culture of “safety first, prevention-oriented, comprehensive management, and full participation.” The company established a safety production management committee to fully implement the safety production responsibility system; developed an annual safety training plan and organized various safety education and promotion activities according to the plan; conducted regular three-level safety hazard inspections and incorporated the rectification of all hazards into performance evaluations; and standardized emergency management work. In 2024, the company did not experience any major safety accidents. On the other hand, production and manufacturing strictly controlled costs, production, and quality management, as well as safety work, and promoted work informatization, equipment automation, and process streamlining to achieve integrated development. The company has continuously strengthened quality supervision throughout the production process, implemented various engineering renovations, and carried out a series of cost-saving and efficiency-enhancing initiatives.

7. Emphasizing environmental protection and promoting green, circular, and low-carbon sustainable development

1. Environmental Management System

Changlan Electrical has always placed environmental protection at the forefront of its corporate development strategy, committed to developing safe and environmentally friendly “green” products to meet the higher demands of society and consumers, emphasizing sustainable development, and striving to build an environmentally friendly enterprise.

As a high-tech manufacturing enterprise, the company has established an environmental policy of “adhering to laws and regulations, energy conservation and emission reduction, pollution prevention, and continuous improvement”; sets annual energy conservation plans; implements strict energy management measures such as energy-saving electricity use, water conservation, raw material conservation, and the use of non-toxic substances; conducts regular energy audits; and engages renowned certification audit companies to conduct comprehensive diagnostics, integration, and improvement planning for the company.

The company actively promotes clean production, conducts strict inspections of raw materials to achieve source control, prioritizes the use of low-toxicity, non-hazardous raw materials, processes, technologies, and equipment, and integrates the management philosophy of “energy conservation, consumption reduction, pollution reduction, and efficiency improvement” throughout the entire production and business operations process to minimize environmental impact.

The company actively promotes its environmental protection policy and relevant national environmental protection policies, strengthens environmental awareness among all employees, and encourages and motivates employees to actively participate in environmental protection initiatives.

2. Achievements in Energy Conservation and Emission Reduction

Changlan Electrical has always taken “waste reduction, energy conservation, continuous improvement, and pollution prevention” as its mission, striving to minimize its environmental impact. The company places great importance on energy conservation and emission reduction efforts, emphasizing the need for enterprises to conserve resources, reduce energy consumption, minimize pollution, and enhance efficiency. In the face of increasingly intense market competition, the company has intensified its focus on technological research and development and process innovation, striving to improve product合格率, reduce product energy consumption, and enhance corporate competitiveness while achieving significant energy conservation and emission reduction benefits and corporate economic benefits. The company has obtained ISO 14001 environmental management system certification and established corresponding comprehensive management document systems, which are implemented in accordance with the system requirements. The company has also obtained GB/T 23331-2020 idt ISO 50001:2018 energy management system certification and obtained the energy management system certificate.

3. Green Manufacturing and Green Supply Chain

Since its inception, the company has consistently adhered to the concept of green development, continuously strengthening the foundations of green design, green production, and green procurement, and steadily advancing the construction of a green manufacturing system, which includes green factory and green supply chain management systems. In 2023, the company was awarded the titles of “Provincial Green Factory” and “Provincial Green Supply Chain” by the Hunan Provincial Department of Industry and Information Technology; in 2024, the company was honored with the title of “National Green Factory.”

While actively fulfilling its corporate environmental responsibilities, the company is committed to driving upstream and downstream enterprises to enhance their green management levels and provide the market with green products throughout their entire lifecycle. Looking ahead, the company will leverage its extensive experience as a national-level green factory to systematically empower suppliers through technical transfers, policy alignment, and supply chain support measures, helping suppliers overcome the bottlenecks of green transformation and transition from “passive compliance” to “proactive green innovation.” This strategic initiative not only actively responds to the national “dual carbon” strategy but also represents a key strategic layout to enhance supply chain resilience and capture green market share, injecting new vitality into the company's sustainable development.

BLOG